“Every stakeholder is equally responsible to make the RMG sector sustainable. We don’t have any alternative to that as 80% of our total exports come from this sector.”

-Ms. Shwapna Bhowmick Mark & Spencer

Bangladesh’s readymade garment (RMG) industry has been a huge success. The industry began in the late 1970s, grew significantly in the 1980s, and peaked in the 1990s. The industry’s rapid growth was made possible by the use of less complex technology, inexpensive and simple-to-operate sewing machines, and a relatively inexpensive and plentiful female workforce. RMG goods have long been a common way for Bangladesh to obtain foreign currency through export, and Bangladesh has long been among the world’s largest export trading countries for RMG and apparel. since its inception, especially during the last three decades, the RMG industry contributed significantly through the creation of a physical infrastructure which is demonstrated by more than 45000 RMG units along with the development of human capital as around 4 million workforces are directly involved in this industry. It has also contributed tremendously through empowering women as almost 90% of its labor force is female which ranked the highest in Southeast Asia. In terms of core economic consideration, RMG holds almost 14.07% of the GDP of Bangladesh as well as 81% of the total export earnings. It has also made a significant contribution by empowering women, with nearly 90% of its labor force being female, the highest in Southeast Asia. However, since the beginning of the twenty-first century, Bangladesh’s RMG and apparel industries have faced difficulties in providing meeting health, social, and environmental compliances in the face of increasingly stringent completion requirements. The requirement of green compliance started soon after the Rana Plaza disaster and since the sustainability and growth of Bangladesh’s RMG industry has been facing significant challenges in this dynamic domestic and international setting.

The garments industry has been a lifeline for the economic development of Bangladesh. Previously, policymakers of Bangladesh were under the false assumption that as being a developing country, Bangladesh doesn’t require to implement environmentally concerned strategies. However, SEHD revealed that localized pollution poses a serious threat to the environment while having an extremely detrimental impact on people’s health. Since then, Bangladesh Govt has imposed rules that industrial units should be located in declared industrial zones rather than in residential areas and industrial units shall not produce sound, smoke, or odor more than the permitted limit. Furthermore, industrial units are required to submit the Initial Environmental Examination (IEE) Report, the Environmental Impact Assessment (EIA) Report, along the design of the ETP and its schedule after receiving location clearance. For facilitating green production practices, Green credit is used by banks and financial institutions to give exclusive credit terms to green factories. Another policy is the environmental tax that enforces duty due to emissions and eventually, this promotes environmentally sustainable green production. Furthermore, the Bangladesh Bank has developed the “Green Transformation Fund,” a $200 million green fund that will provide low-cost loans for green growth in the RMG and other export-oriented industries. The low-interest loans can be utilized to encourage sustainable practices in areas like waste management, energy efficiency, renewable energy, and recycling.

Since most of the buyers of Bangladeshi-produced RMG products are from Europe and America, foreign buyers such as H&M, Levi’s, M&S, etc are constantly putting influence in making the producers of RMG products becoming green. The producers of RMG products are becoming more environmentally concerns in reshaping their expansion and growth

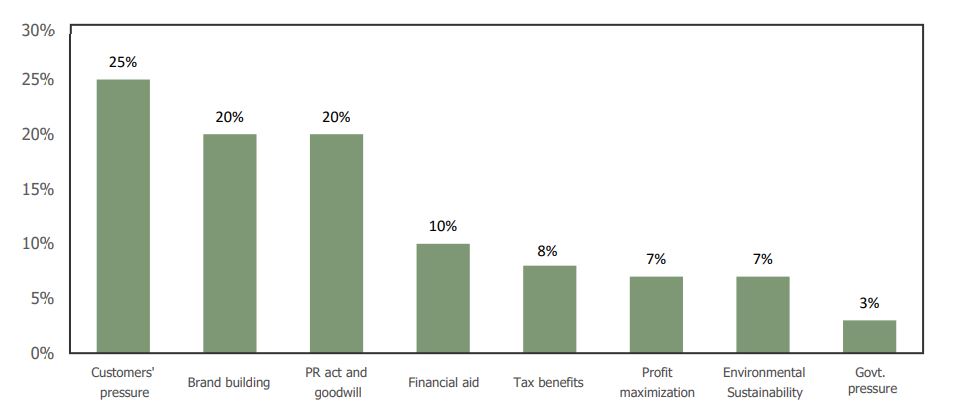

Organizations’ philosophy and motivation towards green production

opportunities because going green not only helps producers in assuring the buyers but also helps companies in getting operational efficiency while improving revenue structure. Going green also helps organizations to enhance their brand image and show society that as a company they care about the people and the environment. While implementing green production, companies can recycle, reuse and redesign their resources which helps in redefining the cost structure. In green production facilities, organizations also need to modify their product processing systems along with procuring green war materials that are environmentally sustainable. Green manufacturers often get access to tax benefits and they are often given awards for implementing the green production process.

Even though green production facilities introduce companies with numerous benefits, companies have to face challenges in implementing the strategies of going green. Government laws and directives are largely in charge of the organization’s green management. However, companies often get discouraged from developing green manufacturing plants due to the government’s shortage of environmental expert services and long-term contracts for adopting green production practices. Even though changes to Bangladesh’s environmental policies, rules, and regulations have been introduced by the country’s legislature, in many instances, these strategies are found to be unpleasant to companies. Moreover, the parties in this industry are often unaware of the necessity of green production, and most of those who know about green production learn through educational institutions on the job learning rather than self-learning. Another reseason for lagging in going green is the general perception as most of them involve parties think green production as a PR stunt for increasing brand image through gaining environment sustainability rather than acknowledging green production as a medium for profit maximization through increased efficiency. Moreover, Lack of buyers’ supports, huge initial investments, lack of operational and technical knowledge, motivation for going green, etc. impacts companies in going green.

In the aforementioned situation, manufacturing units in the RMG sector face various challenges in the process of going green. However, the government of Bangladesh is still working to address all issues so that Bangladesh’s economy remains stable, with the RMG sector serving as the country’s lifeline. Efforts and supports from individuals who are involved in this industry are required to make this dream of becoming green successful as without combined efforts this would never be possible.